America has stopped supporting manufacturers of critical electro-mechanical components

It is too easy for young engineers and supply chain professionals to choose suppliers in foreign countries because of cost/lead-time/volume. We need to change that.

This site is dedicated to connecting YOU with American slip ring companies.

What is a Slip Ring?

Imagine you have a rotating joint. This could be a radar, CT scanner, or a satellite’s solar panels. You have an end effector that needs power, but you have a problem . . . it is constantly spinning. If you were to pass wires through or around the joint, after enough turns the wires would break.

This is where a slip ring comes in. Using conductive brushes and rings (there are other mechanisms that work as well), a slip ring allows you to pass power/signal through a rotating joint.

History

The basic principle of slip rings can be traced back to the late 19th century when they were initially used in early electrical experiments and the development of electrical generators and motors. With the advent of the Industrial Revolution and the increasing demand for electrical power, the technology behind slip rings started to evolve. They became essential components in large-scale electrical machinery, such as turbines and generators, allowing for the transfer of power and signals in machines where a part of the machinery needed to rotate continuously. The mid-20th century saw significant advancements in materials science and manufacturing processes, which led to new materials for brushes and rings, such as silver and graphite which reduced wear and improved the efficiency of power and signal transmission.

Basic Slip Ring Fundamentals

Packaging:

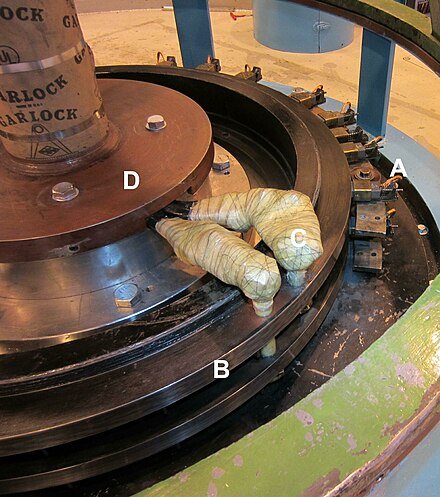

Slip rings are unique components where in some applications having a stand-alone assembly makes sense. However, if the slip ring is integrated into a larger assembly and packaging space is at a premium, you can by the rings and brush separately and package them yourself.

Slip Ring Separates - brushes and rings sold as separate assemblies that you would then integrate into a rotary joint

Slip Ring Capsule - a pre-packaged set of brushes and rings already constrained together and often weatherproofed.

Configuration:

How the brushes and rings are configured is also important. If radial width is critical then you want to use a drum-style slip ring that has rings stacked. If axial height is a premium then you want to use a pancake slip ring that positions the rings concentric to each other.

Drum - rings are stacked along a centerline

Pancake (or platter) - concentric rings -> usually worse performance than a drum

Leads:

Well, the whole point of a slip ring is to pass electrical current mechanically so how you interface with that is important. If you buy an off-the-shelf slip ring most likely you will be given “flying-leads” which means bare wires that you are expected to crimp/solder. These wires can either come out of the slip ring radially or axially. Now if you are working with a slip ring company to make a custom slip ring for your application, you can ask for connectos. These can either be attached to the leads mentioned earlier or built into the casing of the slip ring.

Axial - leads come out vertically, usually both sets on the same side.

Radial - leads come out on the outside of the slip ring on the cylindrical face.

Connectors - these are custom and can be whatever you would like. RJ45 is common for ethernet and Mil-Spec connectors are common for high IP-rated slip-rings.

Key Slip Ring Variables

There are 9 key variables you need to think about when selecting your slip ring (and this dictates which company to go with).

IP Rating

I’ll direct you here for the full breakdown, but generally speaking, the first number is dust protection and the second is water protection. Slip rings usually fall into 2 categories, sealed (IP54 to IP68) or open (IP00-IP43), it’s kinda of a spectrum so it really can vary from supplier to supplier, and be careful, just cause they give it a rating doesn’t mean it has been tested.

RPM

RPM requirements tend to break into 3 groups. 1-100 RPM, 100-1000 RPM, and 1000+ RPM.

1-100 RPM is easy. Any Amazon/Alibaba purchased slip ring will be able to handle this range and the MTTF (Mean Time To Failure) can be quite long. Expect crappy bearings (or bushings). This range also tends to be the limit for most ethernet slip rings.

100-1000 RPM tends to be similar designed slip rings to the 1-100 RPM range but with nicer bearings and high-quality materials (silver/graphite).

1000+ RPM is usually the range of Oil/Gas drilling slip rings. These things are crazy expensive and have short lives.

A word of advice. Specify 20-30% higher RPM requirements in order to give yourself margin as most slip rings are hand made and there tends to be a decent amount of variance between each ring you will get.

Temperature Rating

The critical components of a slip ring (the brushes and rings) don’t tend to be affected much by temperature (when in a reasonable range where thermal expansion doesn’t play major factor). Instead, temperature tends to drive adhesive selection and the material of the cast/compression molded plastic that holds the brushes/ring.

Number of Rings

The number of rings usually just dictates the Z height of the slip ring. Every company will have a minimum ring height driven by the voltage requirement you provide and the dielectric strength of the material spacing the rings. After that, it is just a question of how much of a wiring mess you want!

Signal Type(s)

The type of signal you are trying to pass through the slip ring drives its architecture. The most common are:

DC Voltage - DC slip rings are the “standard”. All companies support passing low DC voltage. As you get above 50V it can get more complicated. Generally, DC current drives ring thickness, and voltage drives ring spacing.

AC Voltage - AC slip rings are usually “thick” as companies need to ensure you don’t turn the slip ring into a huge modulating antenna.

Ethernet - Ethernet slip rings are a tricky beast. True Gigabit ethernet requires 8 rings with very very low noise. It is a relatively new capability and only a few companies support it.

Other types of signals I have seen include coax, fiber, and thermocouples (sometimes even in measuring the inside of the slip ring)

Max Current

Most slip ring companies support up to 50A per ring. Beyond that, you dive into the heavy heavy machinery slip rings, which exist, but tend to be custom. With DC voltage it can sometimes be cheaper to run multiple rings of a lower current and then splice the input/output wires.

Brush Material

Brush material is the secret sauce of any slip ring company. Usually, it is a blend of graphite and a precious metal. Silver is used for high-quality DC slip rings while gold is used for sensitive signals like ethernet.

Ring Material

Ring material pairs with brush material. Often they are the same to reduce wear/impedance. Ring quality is a major differentiator between crappy Chinese slipe rings and trusted American ones!

Thru Bore Size

Often you want to run something through the center of your slip ring. This can be a shaft to provide bearing support to whatever you are rotating. The thru bore can also be used to transport fluids/gasses in what is often called a fluid rotary union (many of the companies below also sell this. Through bore size can drive up price because a larger ring sees a higher surface speed thus is similar to a much higher RPM small slipe ring.

American Slip Ring Companies

Location: Carlsbad, CA

Email: sales@mercotac.com

Phone: (760) 431-7723

It’s in the name, Mercotac sells brushless slip rings that use mercury.

The pro is a significantly longer life.

The con, there is mercury and they aren’t IP 68. But if you need 2-8 leads passed through a moving joint these could be a great option!

IP51

1-8 Rings

-29 to 60 °C

AC, DC

300-7.5k RPM

30A

N/A

None

N/A

Location: Waverly, Iowa

Email: info@uea-inc.com

Phone: (800)-394-9986

United Equipment Accessories is one of the bigger players in the industry. They offer large slip rings and can integrate hydraulics.

The downside is that they probably move on the slower side of things.

IP68

1-120 Rings

-40 to 93 °C

AC, DC, Ethernet

3,000 RPM

1000A

Graphite, Silver

.5” to 14”

Brass, Silver

Location: Christianburg, Virginia

Email: rotarysolutions@moog.com

Phone: (540)-552-3011

MOOG is the heaviest hitter in the US Market. They make slip rings for defense companies, major industrials, and aerospace. They know slip rings better than anyone (look how extensive their catalog is). Unfortunately, because they are so large, they move slowly and don’t work with small companies

IP65

1-72 Rings

Unkown

AC, DC, Ethernet

20,000 RPM

500A

Gold, Silver

1.5” to 9”

Gold, Silver

Location: Ramsey, Minnesota

Email: info@rotarysystems.com

Phone: (800)-959-0146

Rotary Systems is a small company that focuses on rotary union devices (think slip ring for fluids/gasses) but also offers power/ethernet slip rings. They are a small well organized business

IP68

1-50 Rings

Unkown

AC, DC, Ethernet

10,000 RPM

50A

Gold, Silver

.5” to 4.75”

Gold, Silver

Location: Ramsey, Minnesota

Email: info@rotarysystems.com

Phone: (800)-959-0146

Princetel is the parent company of Wendon which makes electrical slip rings. They specialize with fiber optic slip rings (high bandwidth)

IP68

Unkown

Unkown

AC, DC, Ethernet

Unkown

Unkown

Gold, Silver

Unkown

Gold, Silver

Location: Waukegan, Illinois

Email: info-US@deublin.com

Phone: 847-689-8600

Deublin is one of the largest slip ring companies in the world. Originally started in the US in the 40s, they now have a massive international presence. Their bread and butter is rotary union joints, but they can do any custom slip ring you could ever want

IP67

1-100 Rings

-20 to 80C

AC, DC, Ethernet

2500 RPM

250A

Gold, Silver

1.5” to 12”

Gold, Silver

Location: Whitestown, Indiana

Email: info@aerodyneng.com

Phone: 317-334-1523

Aerodyn focuses on extremely high rpm slip rings in the oil drilling and turbine space. They offer coolant-filled slip rings that can spin up to 100,000 RPM.

IP68

1-744 Rings

-80 to 200C

AC, DC, Ethernet

100,000 RPM

Unknown

Gold, Silver

Unkown

Gold, Silver

Location: Milford, Michigan

Email: info@aerodyneng.com

Phone: 248-685-3939

Michigan Scientific produces high quality slip rings focused on instrumentation in scientific applications. Their rings can handle high RPMs and high data rates, but don’t pass high currents

IP68

1-60 Rings

-40 to 121C

DC, Ethernet

10,000 RPM

2A

Gold, Silver

0” to 2”

Gold, Silver